Fritz Hansen Grand Prix Chairs

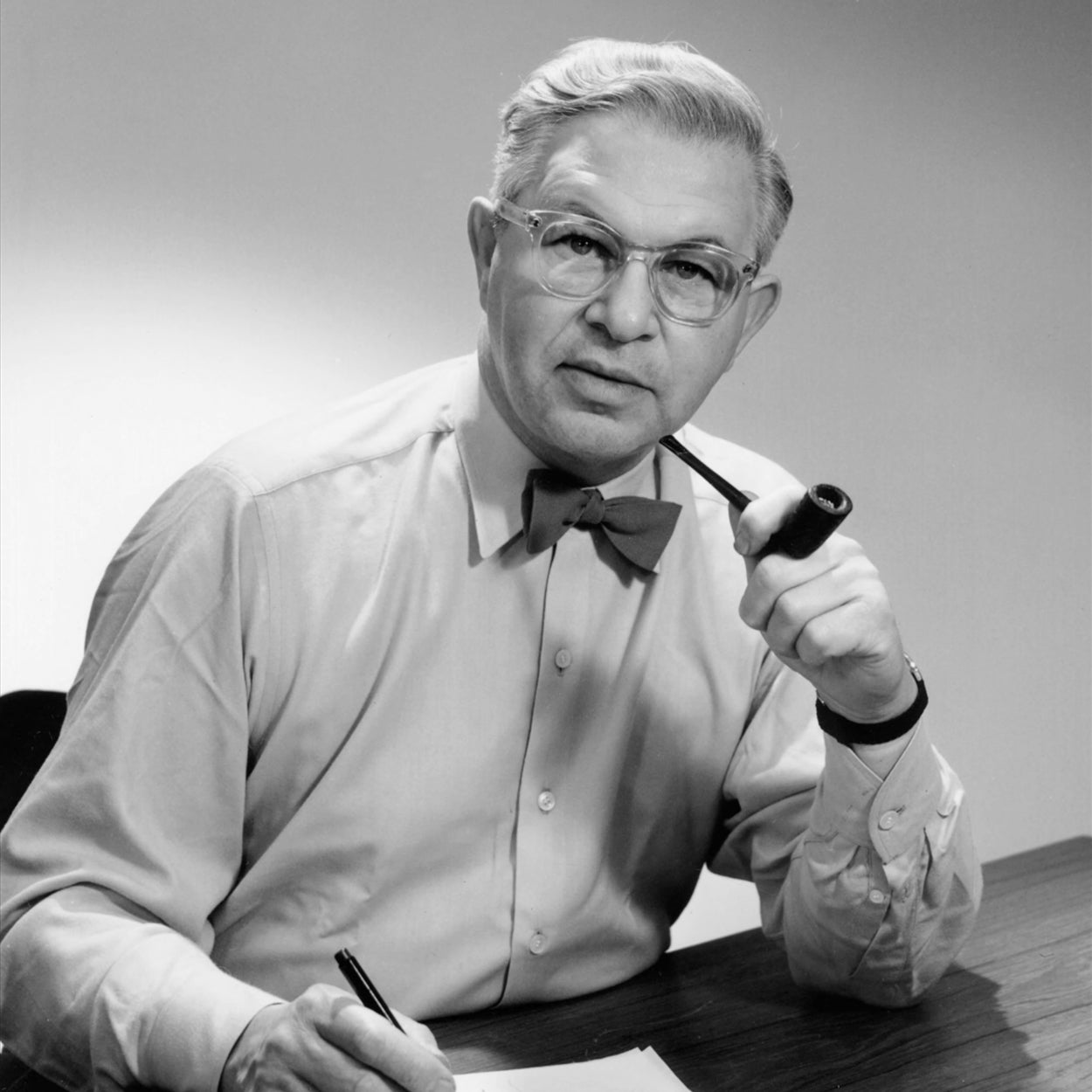

Arne Jacobsen

The Grand Prix™ chair is a chair with graphic edge. It was introduced at the Designers’ Spring Exhibition at the Danish Museum of Art & Design in 1957. Later that year, the chair was displayed at the Triennale in Milan where it received the Grand Prix, the finest distinction of the exhibition.

Models

3130: Chair w. tube legs (stackable up to 5 chairs*)

3131: Chair w. swivel base and castors

3138: Counter stool w. tube legs

3139: Bar stool w. tube legs

4130: Chair w. wooden legs

* Upholstered chairs must be stacked with protection in between each chair.

Materials

Shell: The shell of the Grand Prix™ chair is made of pressure moulded veneer - 7 layers of inner veneer and 2 layers of outer veneer on front and back. The inner veneer is always beech and the outer veneer is available in 2 different natural veneers (Oak and Walnut). The chair is also available in two finishes: Coloured ash or Lacquered, in 16 different colours. All models are also available with front or full upholstery in textile or leather. Model 4130 is also available in Coloured ash in select colour configurations.

Base: The base for 3130, 3138 and 3139 is made of 14 mm steel tubes with 4 legs and leg ferrules of black synthetic material. The base is mounted with black support spacers and a black cover cap. The swivel base for 3131 is made of 14 mm steel tubes and 5 hard-wheel castors with aluminium caps (soft wheels are also available). The bases are available in chromed steel or powder coated steel in 6 colours. The base for model 4130 is made in veneer matching the veneer or colour of the shell (non-stackable).

Model 3130 is available in 3 seat heights: 43/46/48 cm. Model 4130 is available in 2 seat heights: 44/46 cm.

Production Process

Shell: The shell is made of laminated, pressure moulded veneer - 9 layers in total. The 2 outer layers are made in veneer of different wood types, the 7 inner layers are made of beech. The veneer layers are glued together with water-based urea-formaldehyde glue. Un-upholstered chairs are coated with polyurethane lacquer, which prevents the emission of formaldehyde.

Upholstery: The shell is padded with polyurethane (PUR) foam. A water-soluble glue is used for bonding of upholstery to the foam and foam to the shell.

Base: The base is made of chromed steel or powder coated steel. Fritz Hansen uses both trivalent chromium (Cr3) and hexavalent chromium (Cr6) for chromium plating. Fritz Hansen will convert to solely using trivalent chromium (Cr3) when the capacity in the Industry allows it. The wooden legs consist of 23 layers of laminated beech veneer with oak or walnut as outer veneer. The veneer is glued together with water-soluble urea-formaldehyde glue.

Arne Jacobsen

The collaboration between Arne Jacobsen and Fritz Hansen dates back to 1934. It was not until 1952 however that the team got its breakthrough with the Ant™. It was succeeded by Series 7™ in 1955, thereby enabling both Jacobsen and Fritz Hansen to write their names into furniture history.